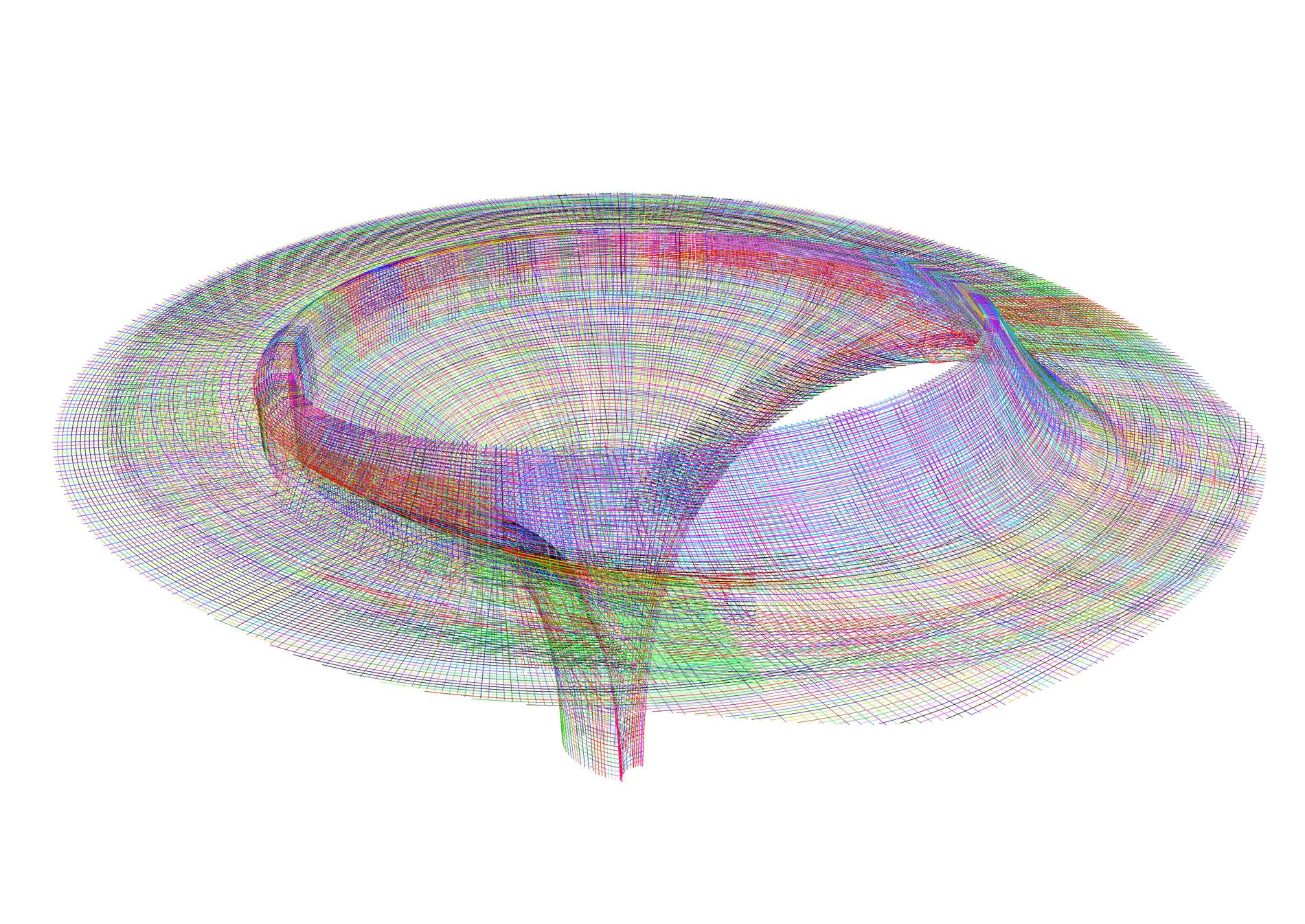

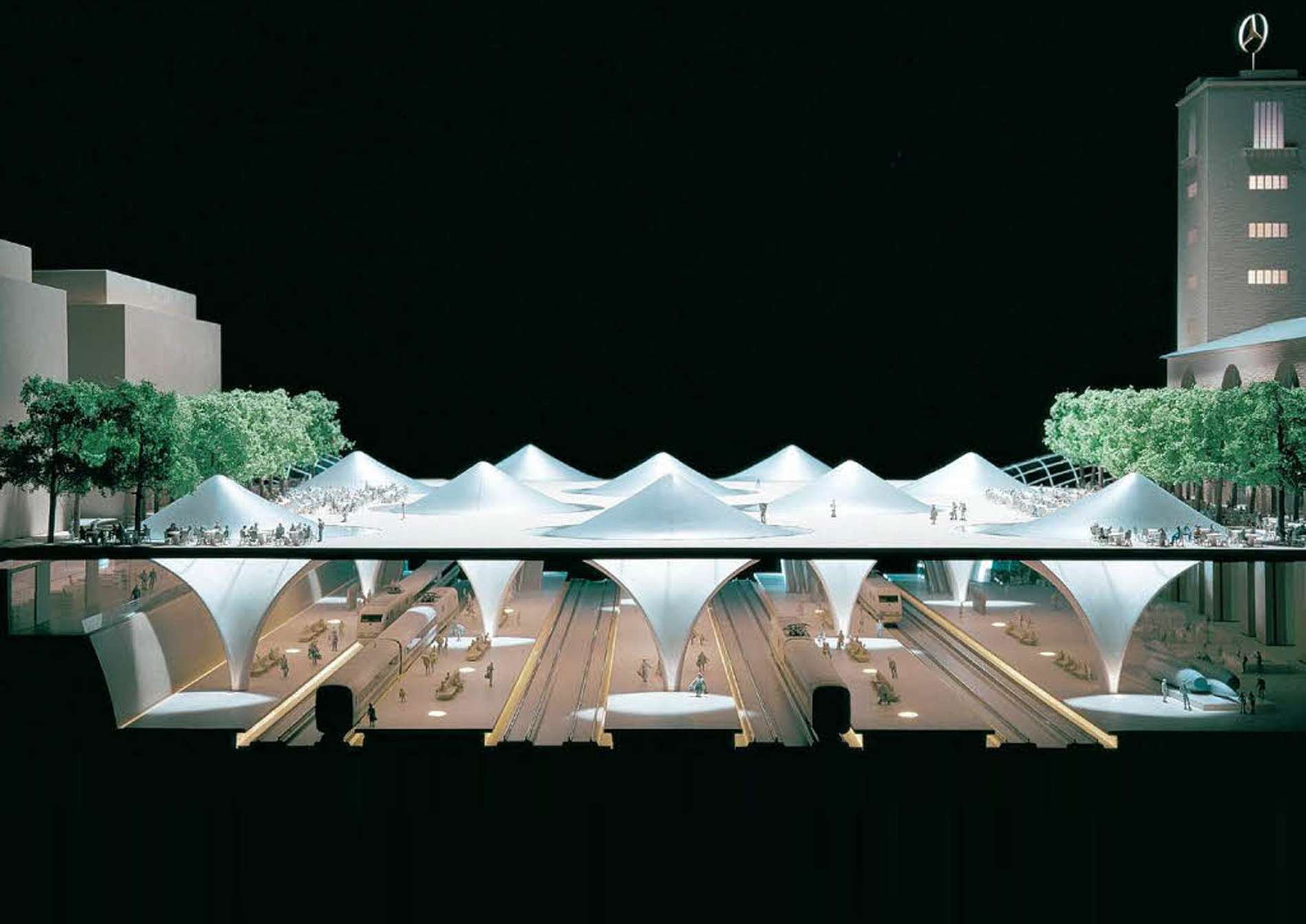

The design of the roof structure of the station is based on highly complex, double-curved surfaces forming individual building parts. The efficient realization of such a geometry demands automated planning strategies.

Stuttgart 21 Reinforcement

Solutions for Building Complex Geometry

The new central station for the Stuttgart 21 infrastructure project by Ingehoven Architects features complex double curved concrete geometries. The roof transforms into 28 structural columns that provide daylight openings for the underground station. ROK's scope of work ranges from shape optimization processes for the reinforcement geometry to automatic reinforcement layout and planning of over 10000 reinforcement elements per column. ROK's customized software solutions allow the generation, clustering and handling of complex data sets to produce detailed reinforcement drawings. ROK was commissioned by the engineers Werner Sobek Stuttgart.

The planning of the reinforcement within the given deadline required optimization processes in close collaboration with the structural engineers.

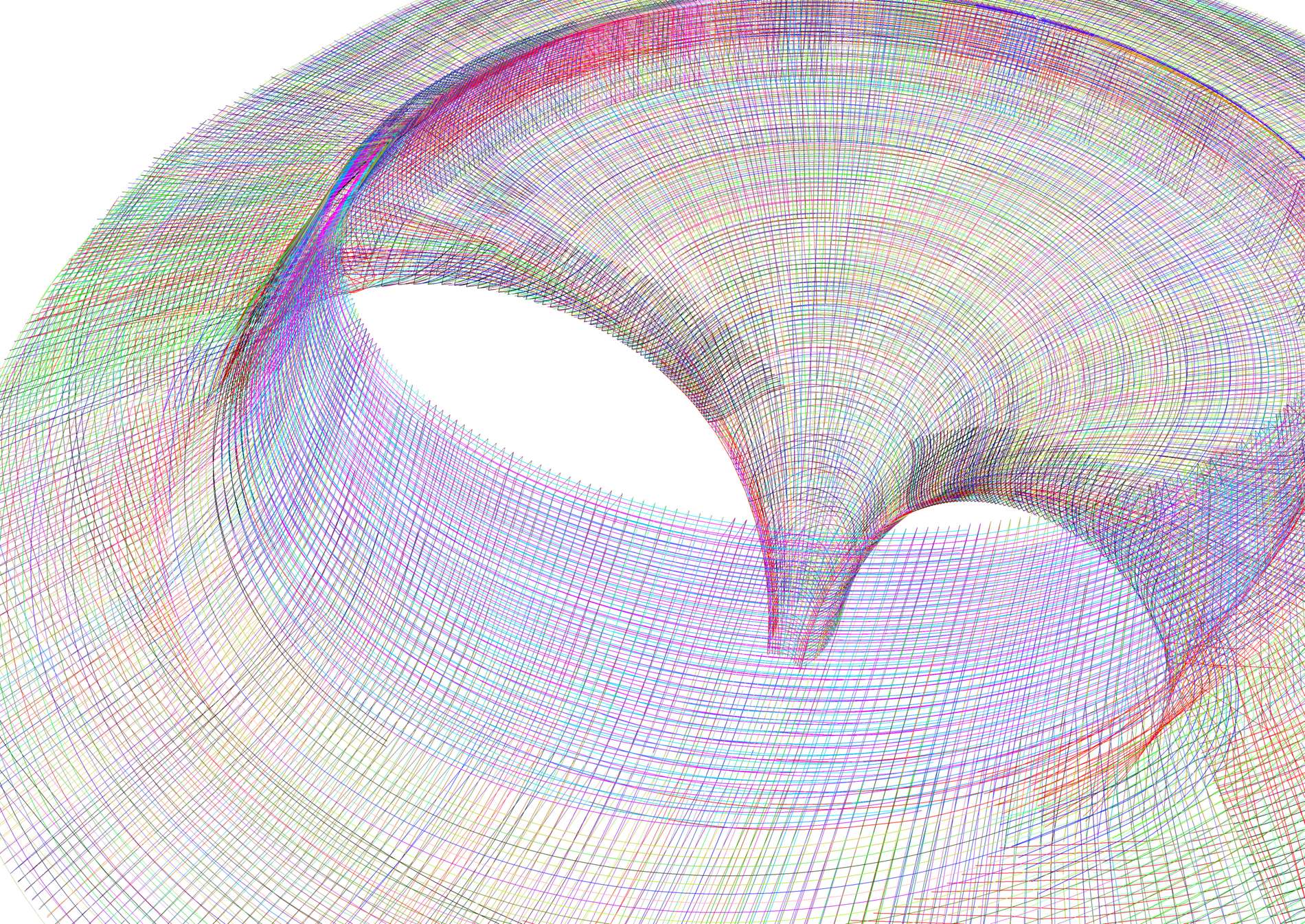

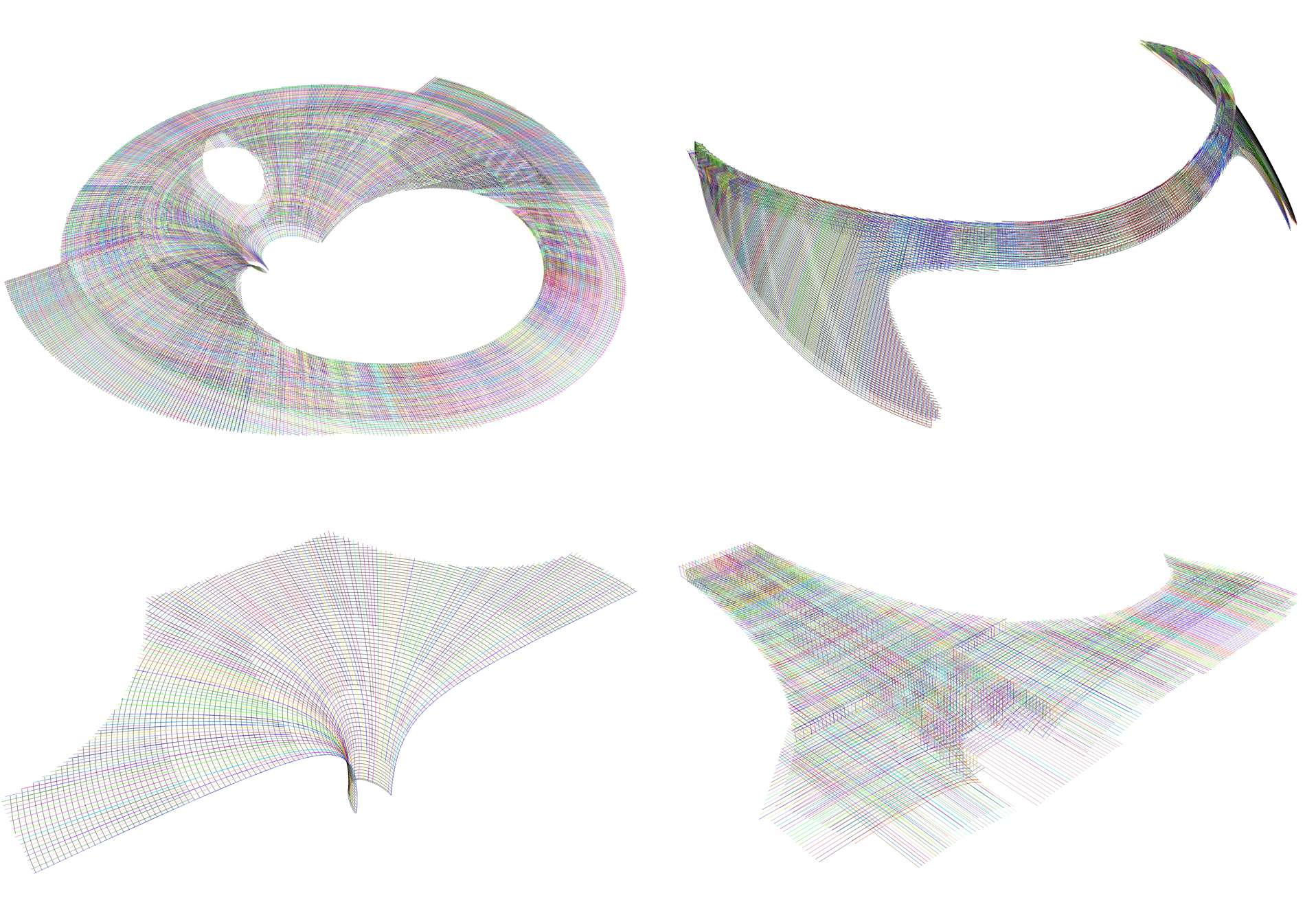

Based on the engineers' calculations and drawings a flexible, parametric model for the generation of thousands of individual reinforcement elements was generated.

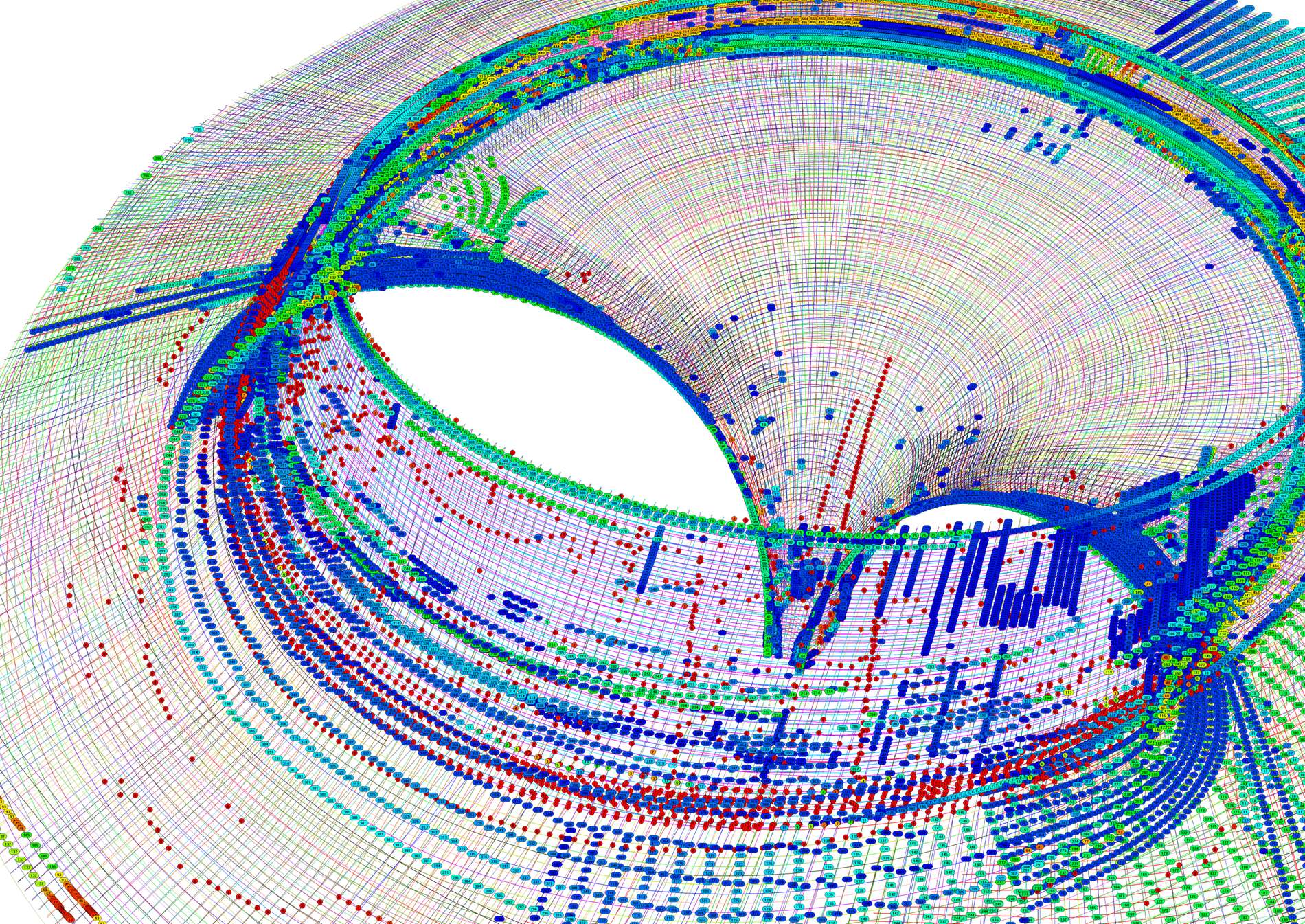

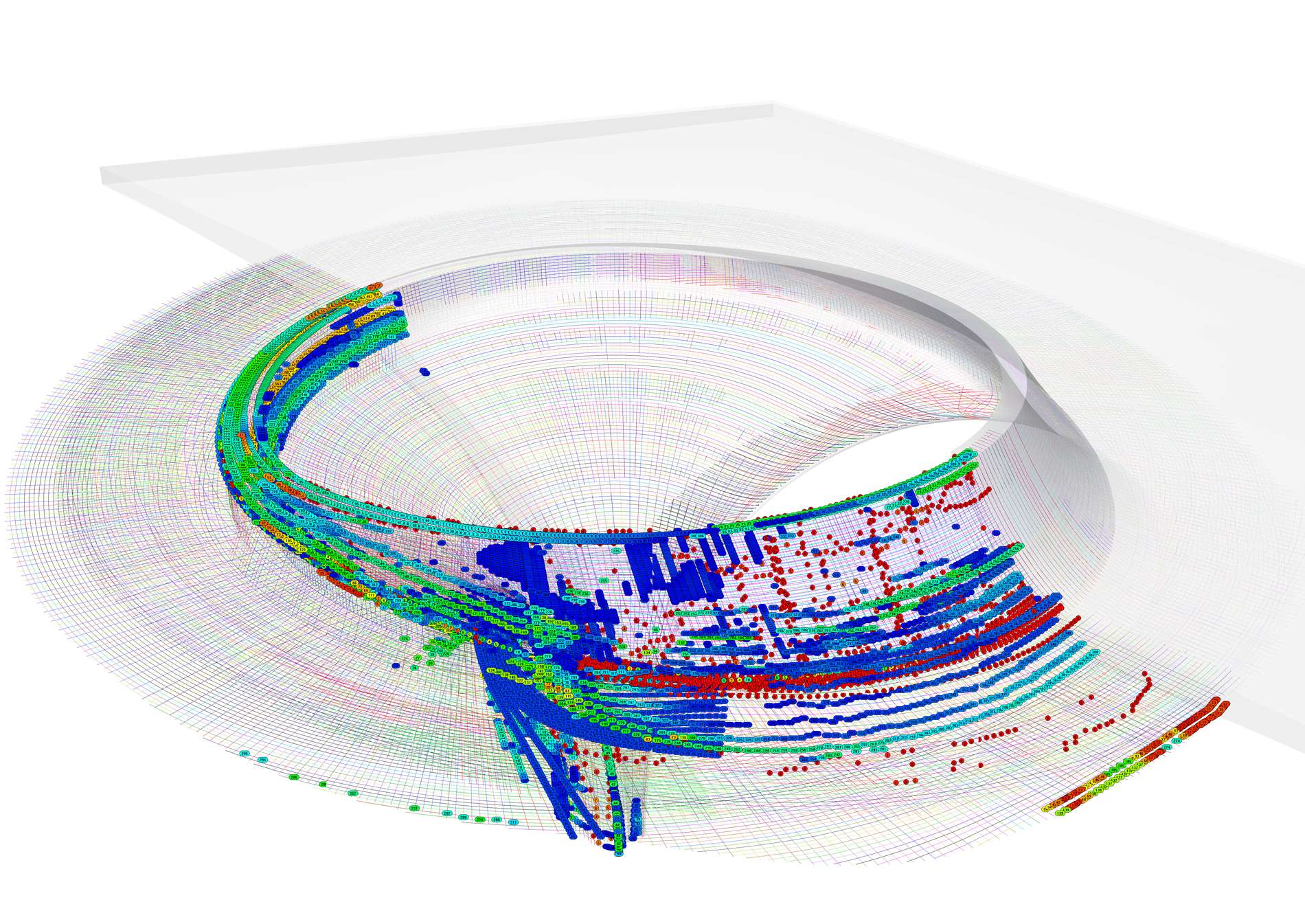

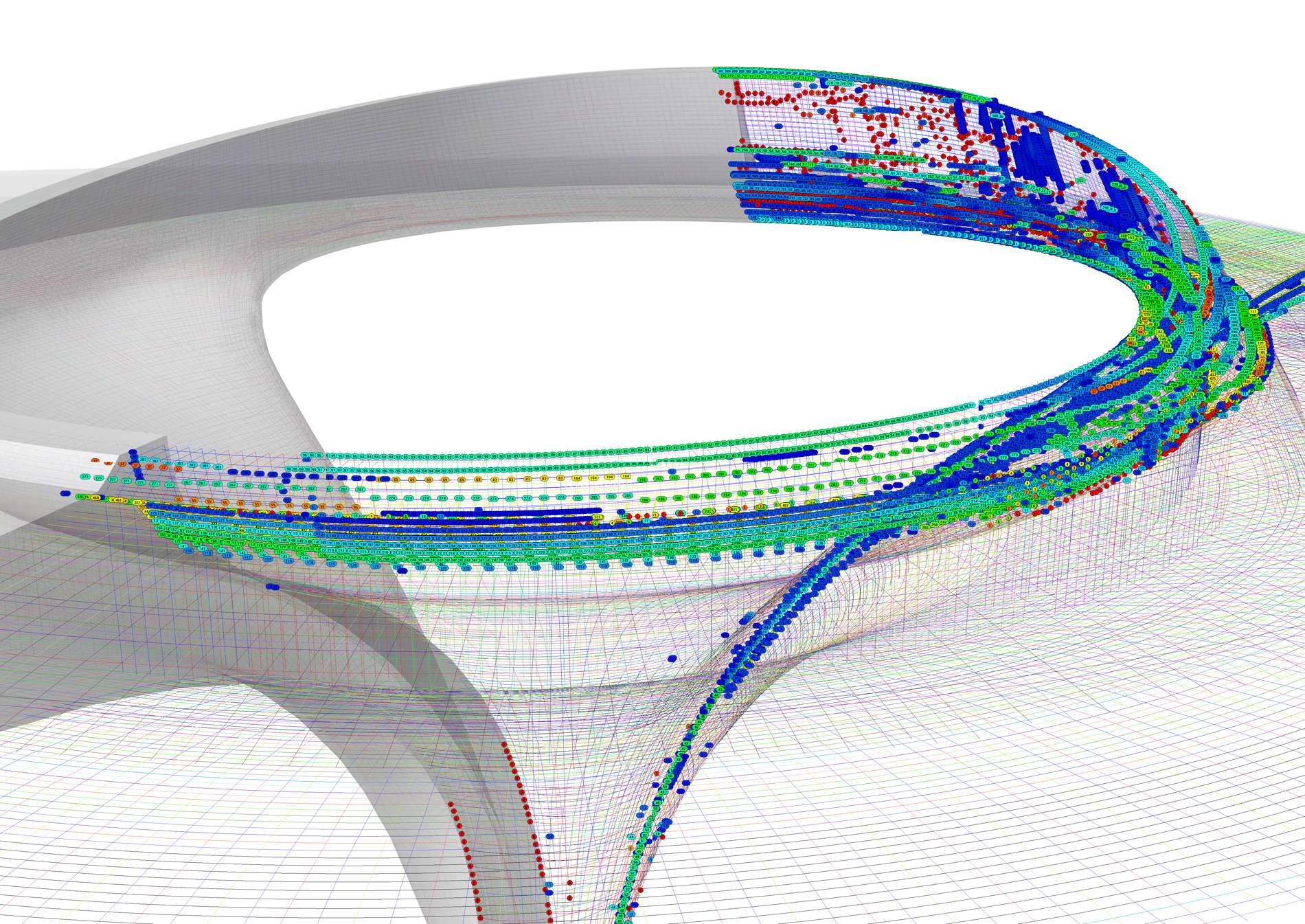

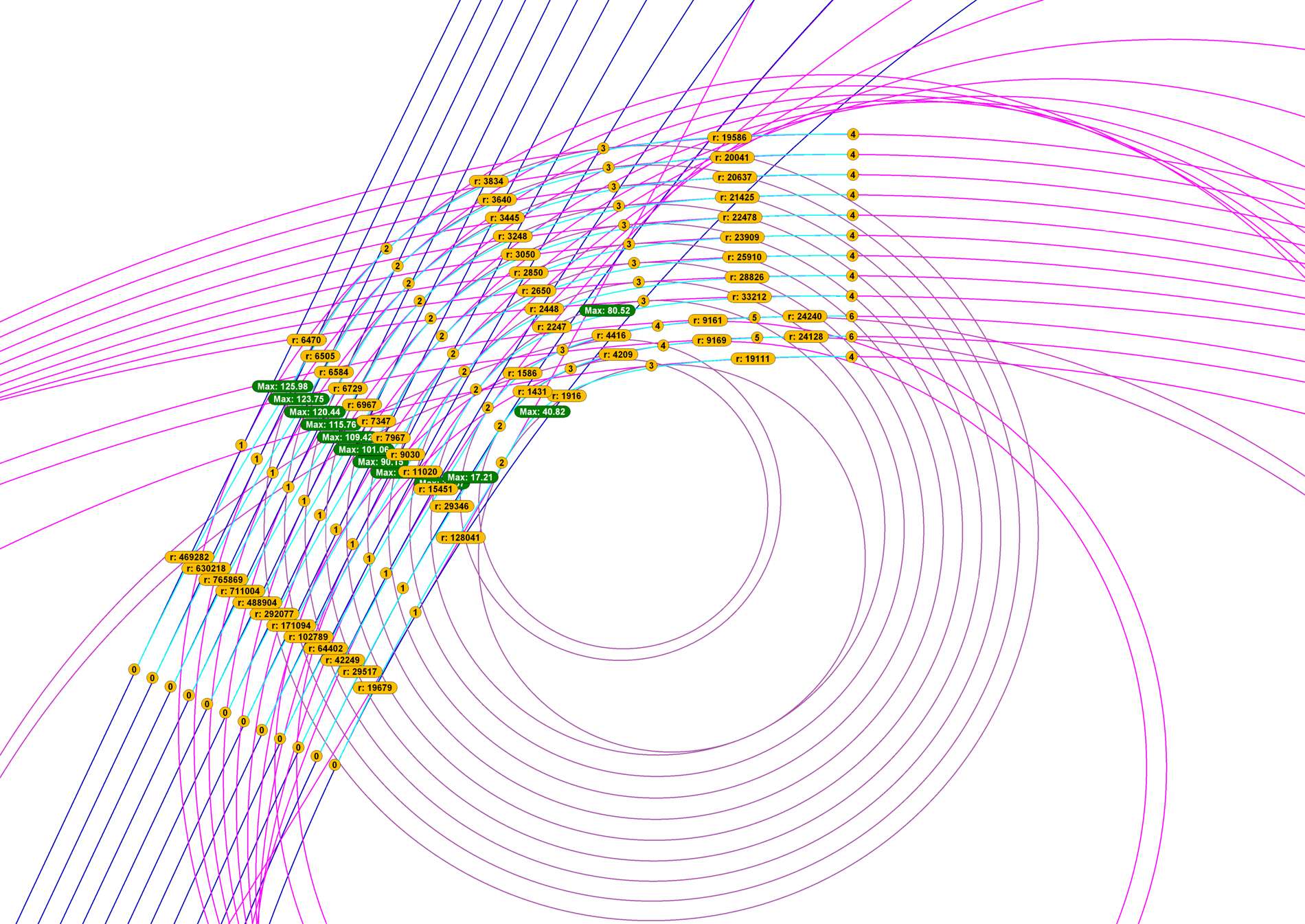

Test routines were used to visualize and verify the reinforcement layout according to the dimensions and tolerances defined by the client.

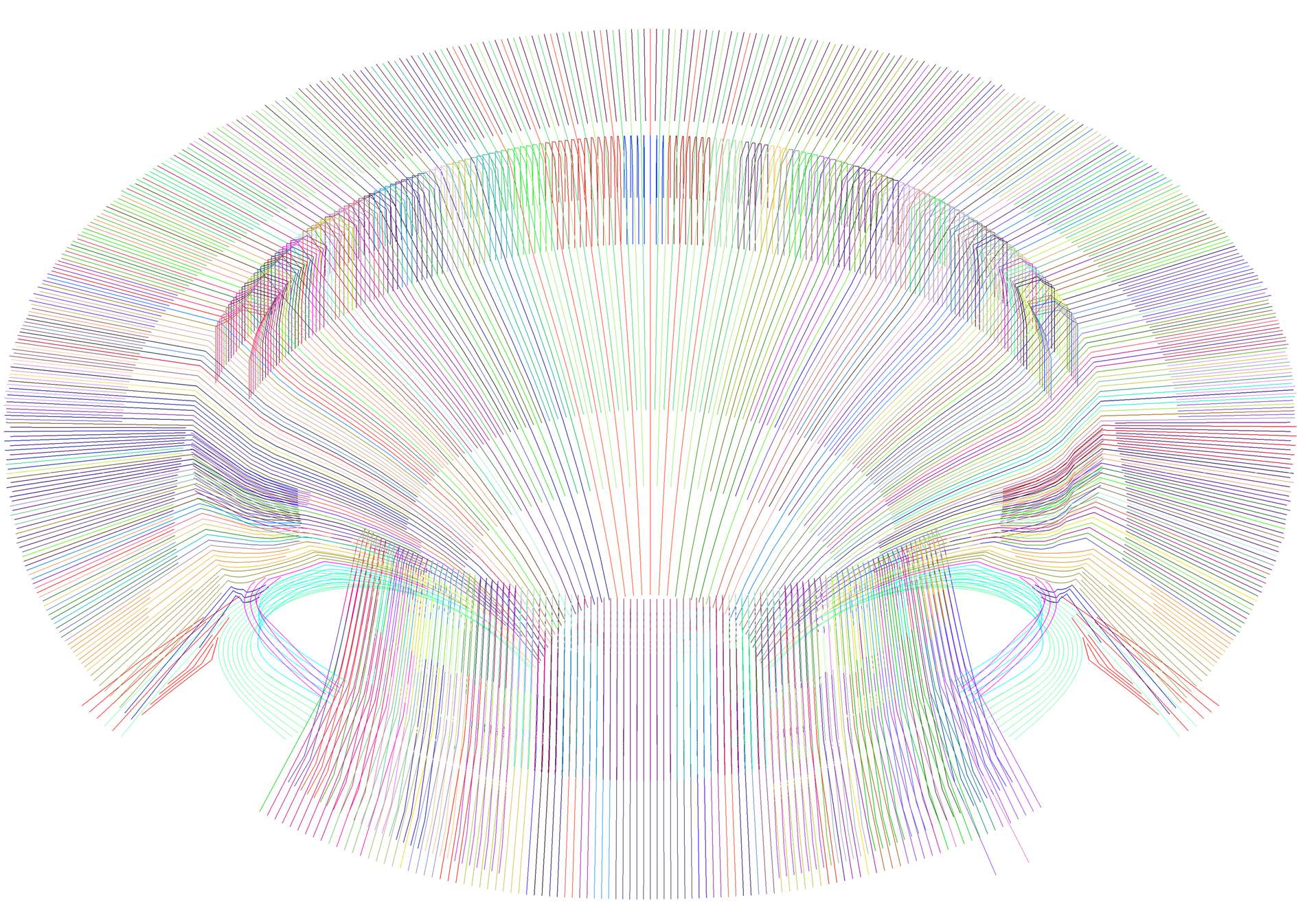

The geometrical input for all automated processes was directly extracted from the architects' digital model.

Special cases could be addressed by manually adding one-off rebar elements and integrating them into the automated process.

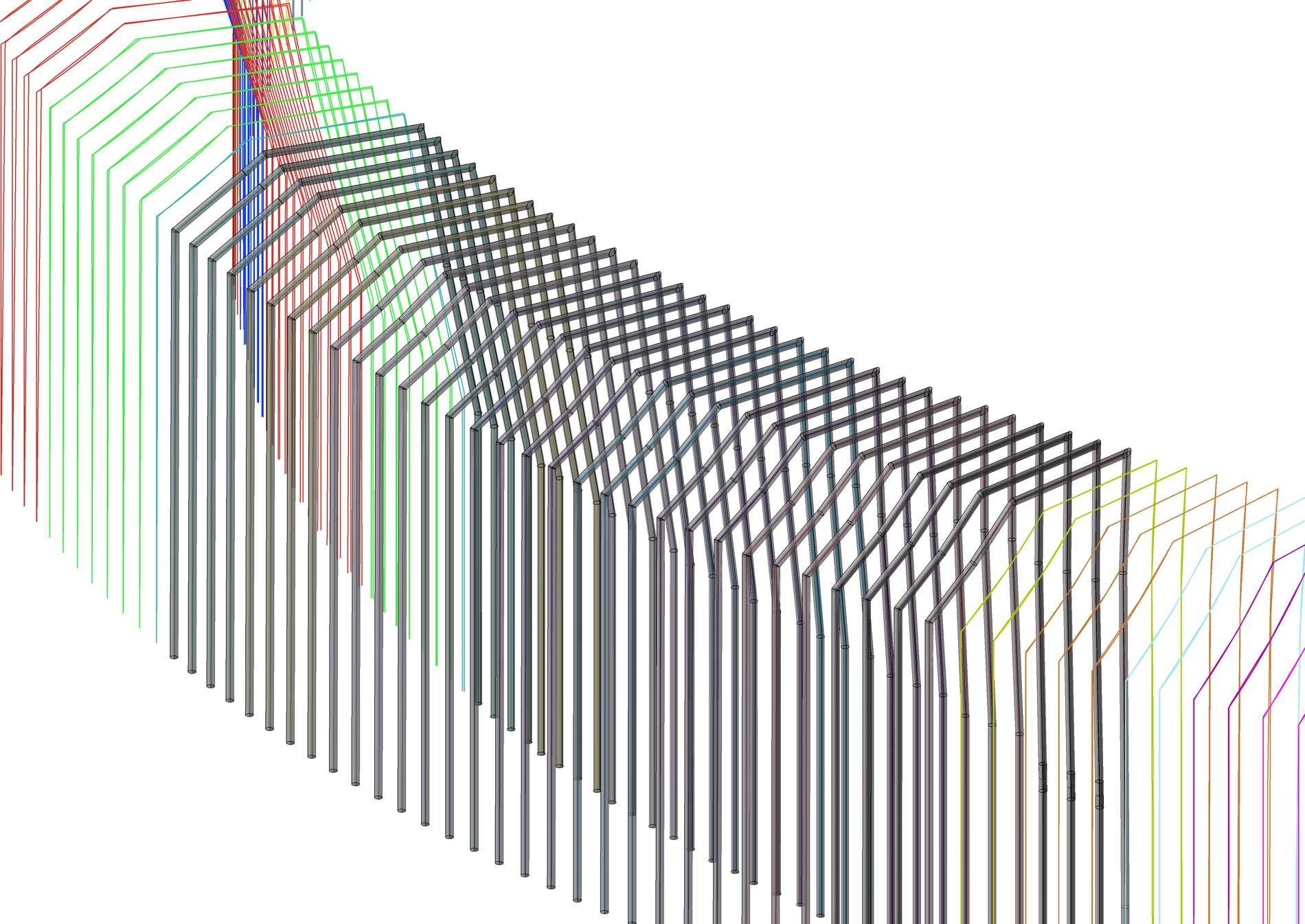

The generalized algorithms were used to generate the configuration of the reinforcement elements for different building parts.

The reinforcement elements were optimized within tolerances to form groups of same radii. Color codes in the 3d model identify them.

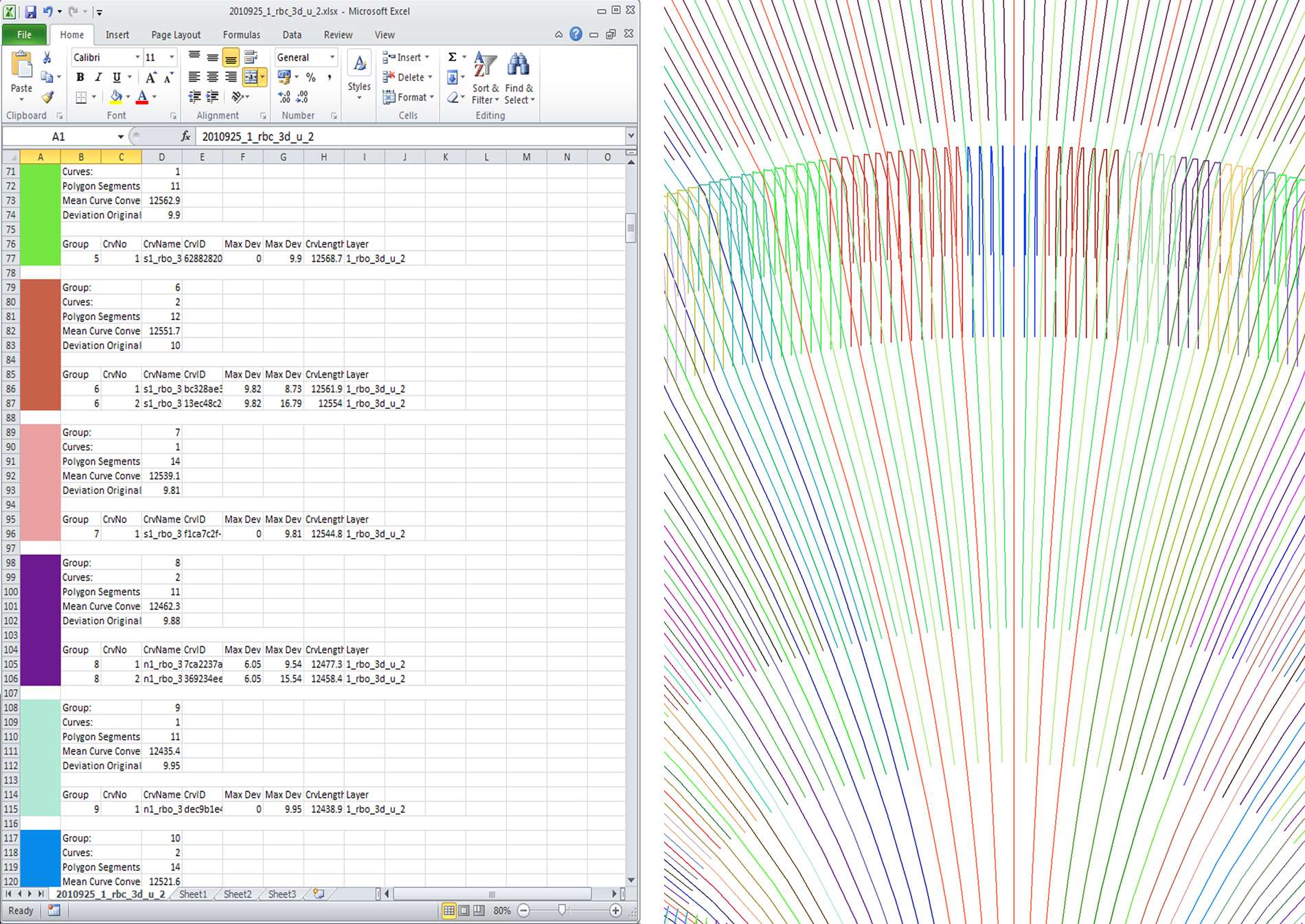

Information about the geometry, location and group membership of all reinforcement elements is automatically provided numerically in a client-specific format.

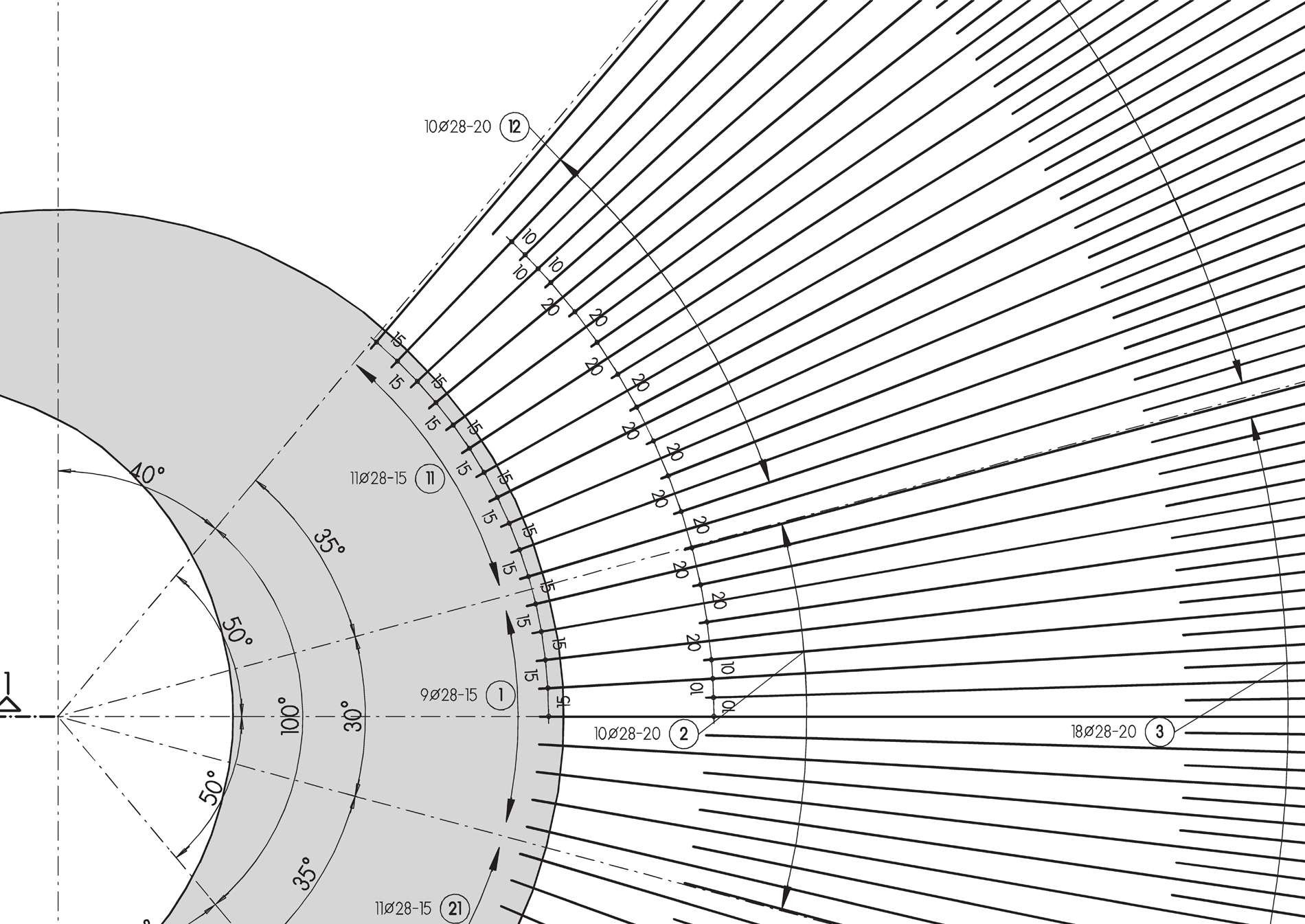

Depending on fabrication constraints of the CNC production, all reinforcement elements are automatically converted into arc segments or special polylines.

The 3D visualization of the actual reinforcement steel with its specific dimensions was used to verify and control each step of the planning phase.

After the digital, three-dimensional generation and verification of the reinforcement layout, the data can be imported to standard reinforcement planning software.

Project Information

Credits

Client

Werner Sobek Design GmbH & Co. KG

Project Partners

Michael Knauss, Silvan Oesterle, Matthias Rippmann